MS Hollow Structural Sections Supplier

As mentioned, MS Hollow Structural Sections can be produced seamless or welded. Seamless MS Hollow Structural Sections are made in two phases, i.e. the first phase consists of piercing an ingot and the second one consists of the elongation of this hollow bloom into a finished circular hollow section. After this process, the tube can go through a sizing mill to give it the required diameter.

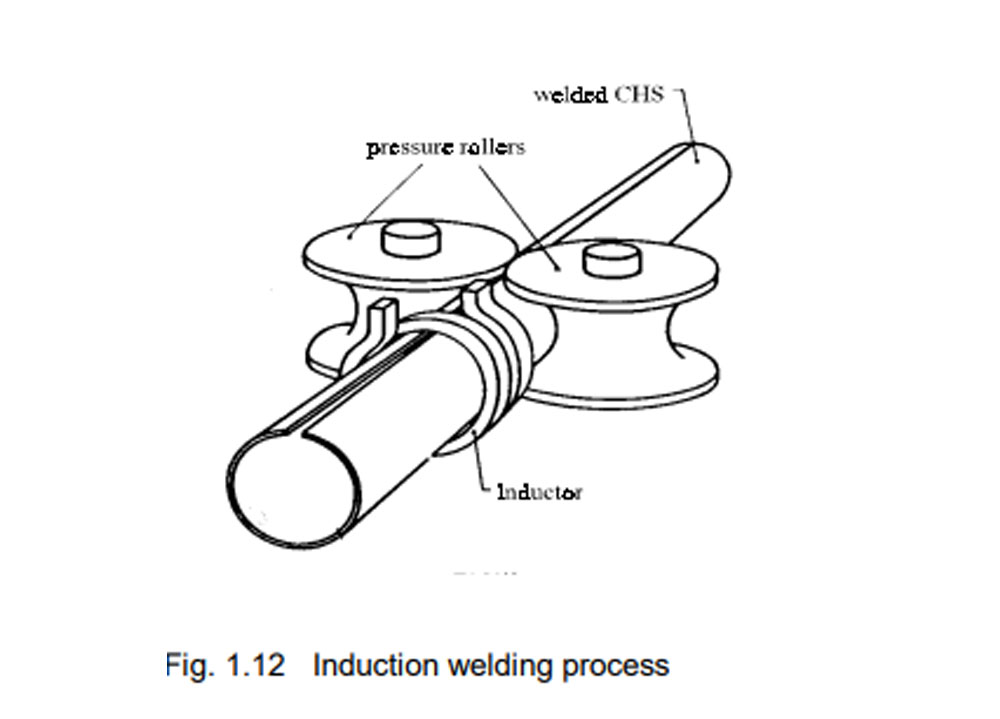

Nowadays, welded hollow sections with a longitudinal weld are mainly made with electrical resistance welding processes or with an induction welding process. A strip or plate is shaped by rollers into a cylindrical shape and welded longitudinally.

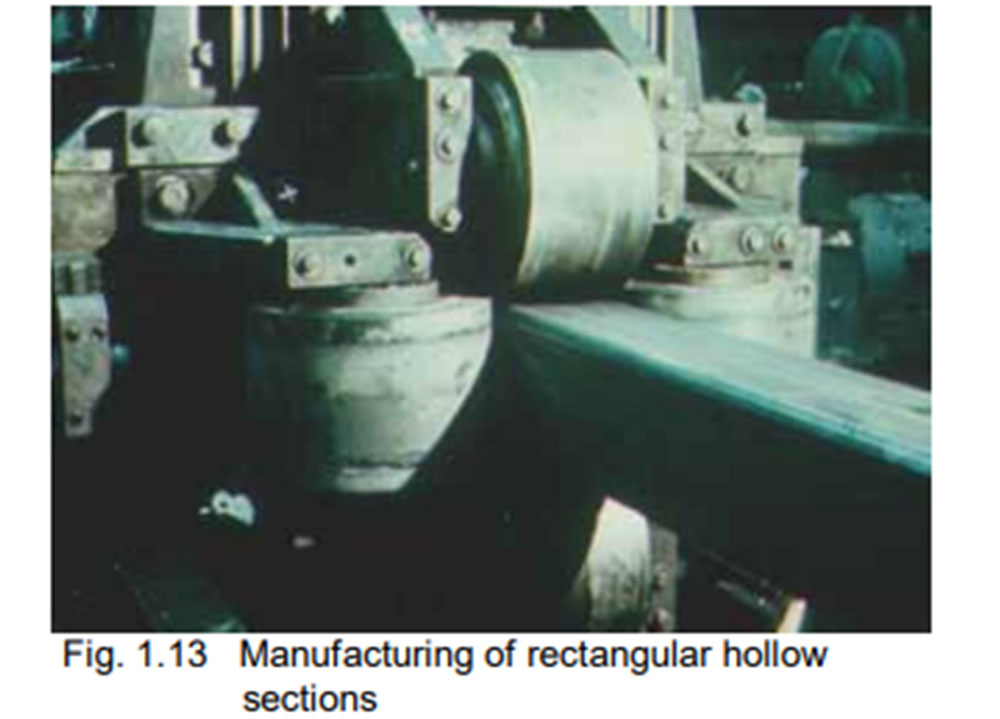

Rectangular hollow sections are made by deforming circular hollow sections through forming rollers, as shown in. This can be done hot or cold and seamless or longitudinally welded circular hollow sections can be used. It is common practice to use longitudinally welded hollow sections. For the very thick sections, seamless sections may be used.

Square or rectangular hollow sections are sometimes made by using channel sections, which are welded together or by shaping a single strip to the required shape and closing it by a single weld, preferably in the middle of a face.

Why Choose SD Ventures as Your MS Hollow Structural Sections Supplier?

SD Ventures is a leading supplier of MS Hollow Structural Sections, with a wide selection of sizes and shapes available. They are dedicated to providing quality products and superior customer service. Here are just a few of the advantages of choosing SD Ventures :

- High quality products

- Competitive prices:

- On-time delivery:

- Technical expertise:

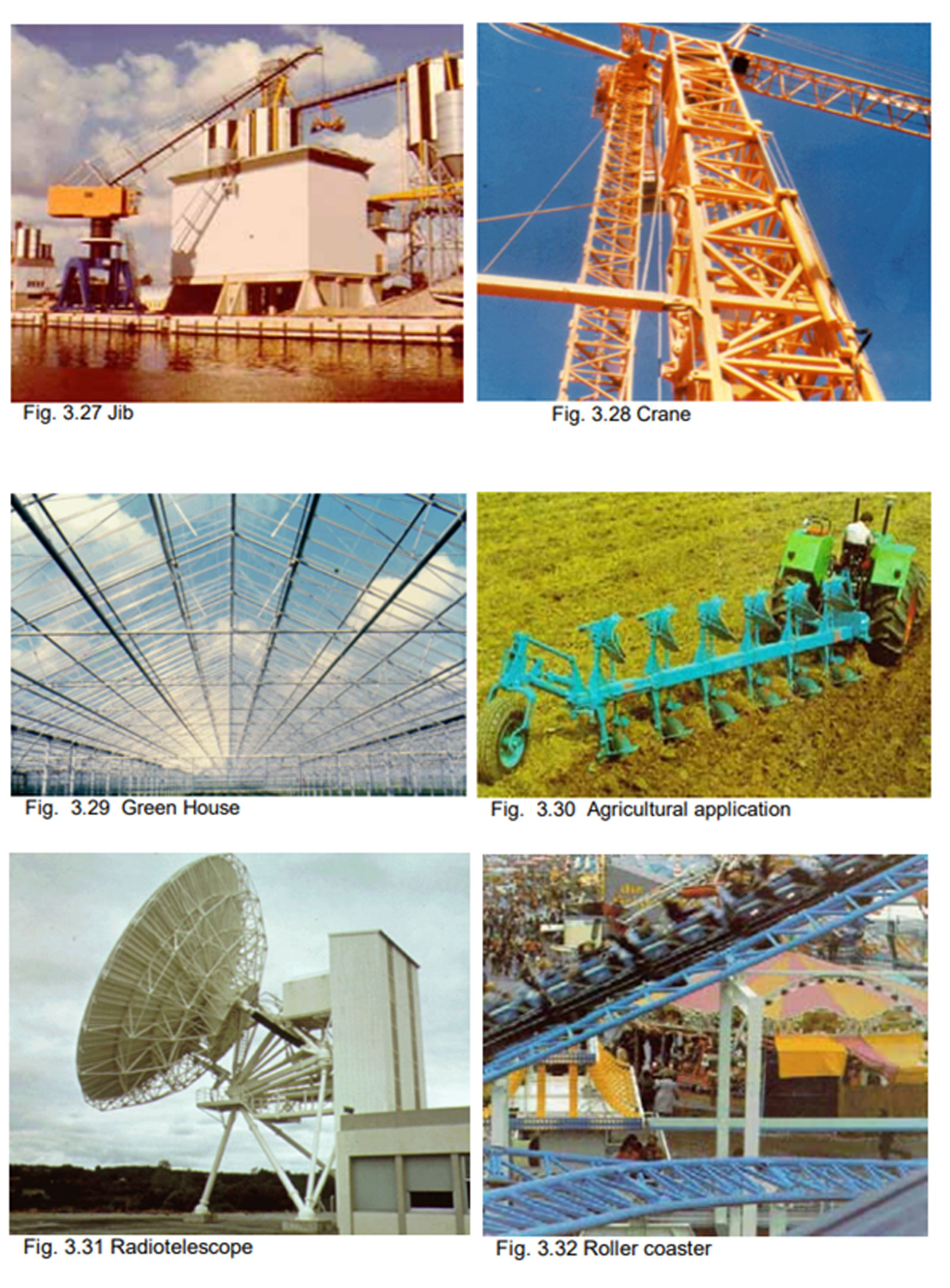

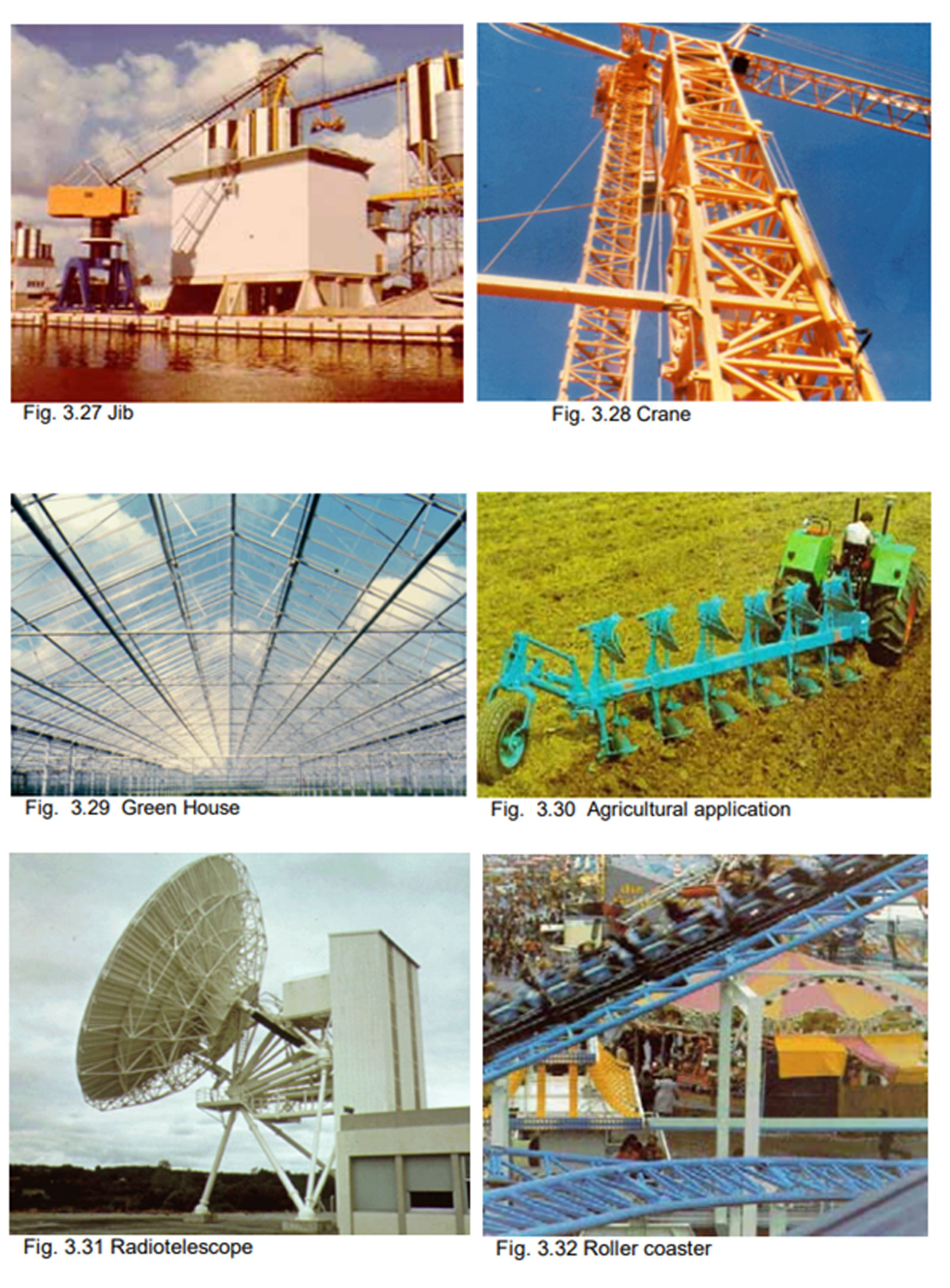

APPLICATIONS

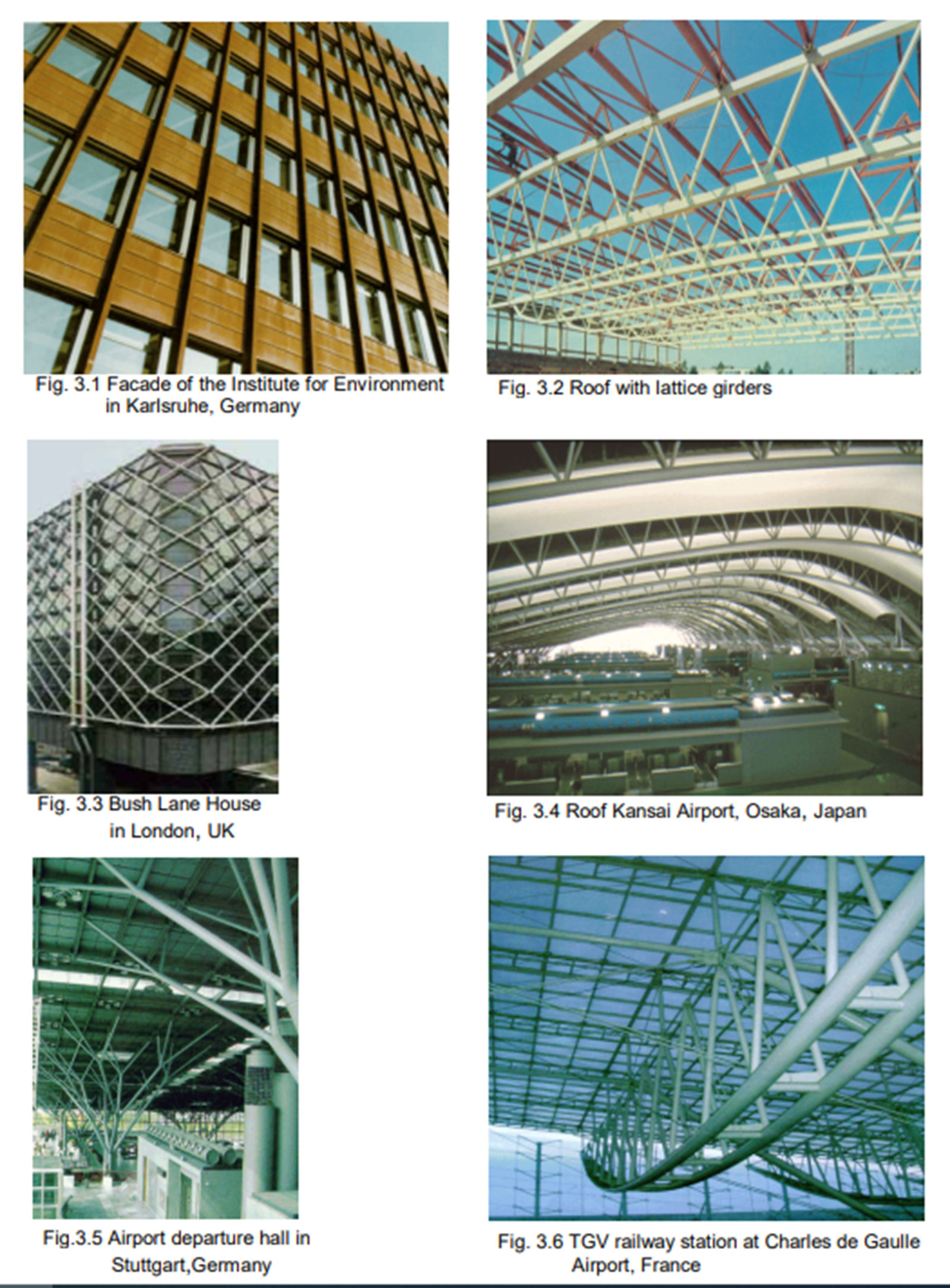

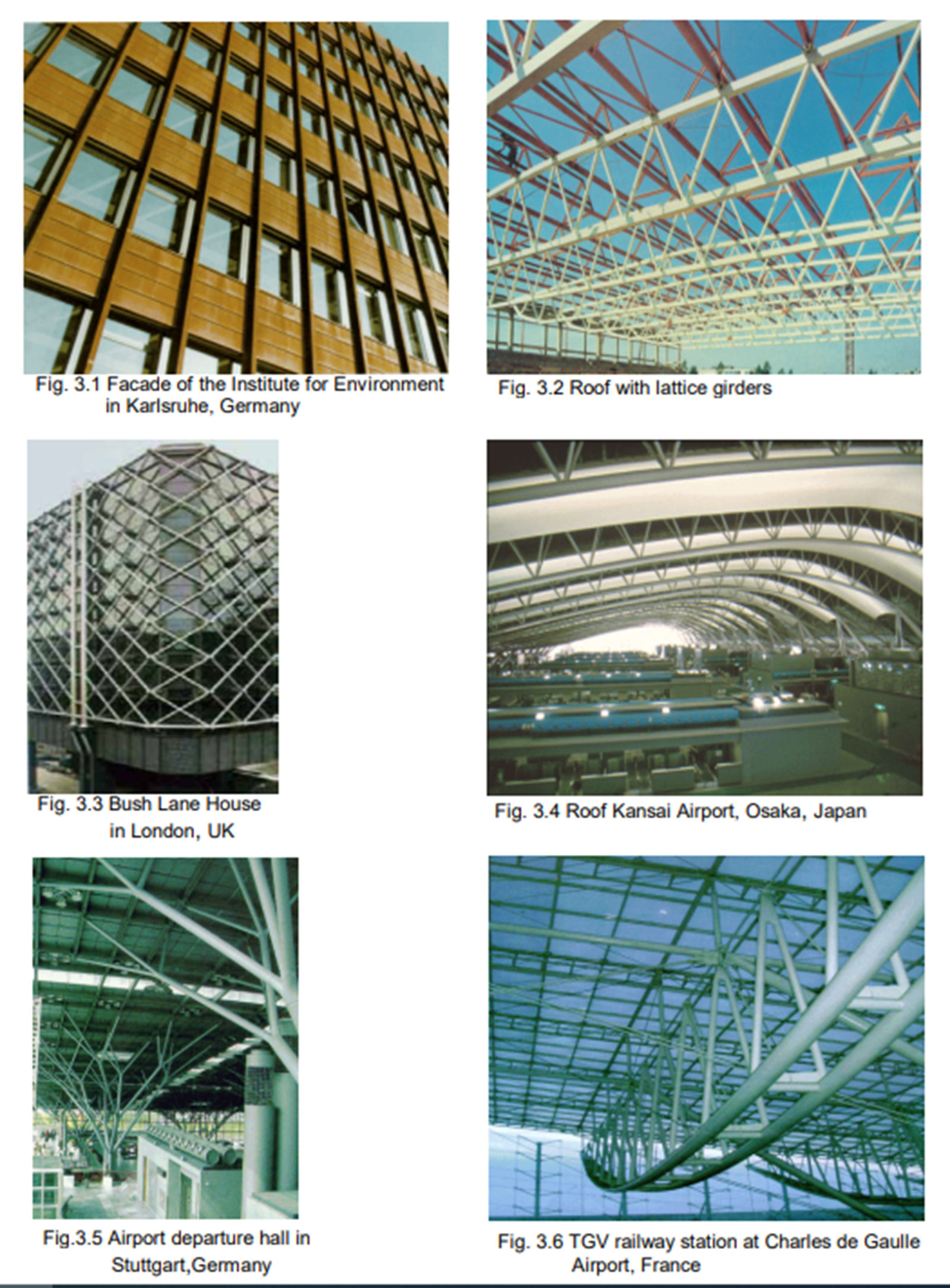

The applications of MS Hollow Structural Sections nearly cover all fields. Sometimes MS Hollow Structural Sections are used because of the beauty of their shape, to express a lightness or in other cases their geometrical properties determine their use.

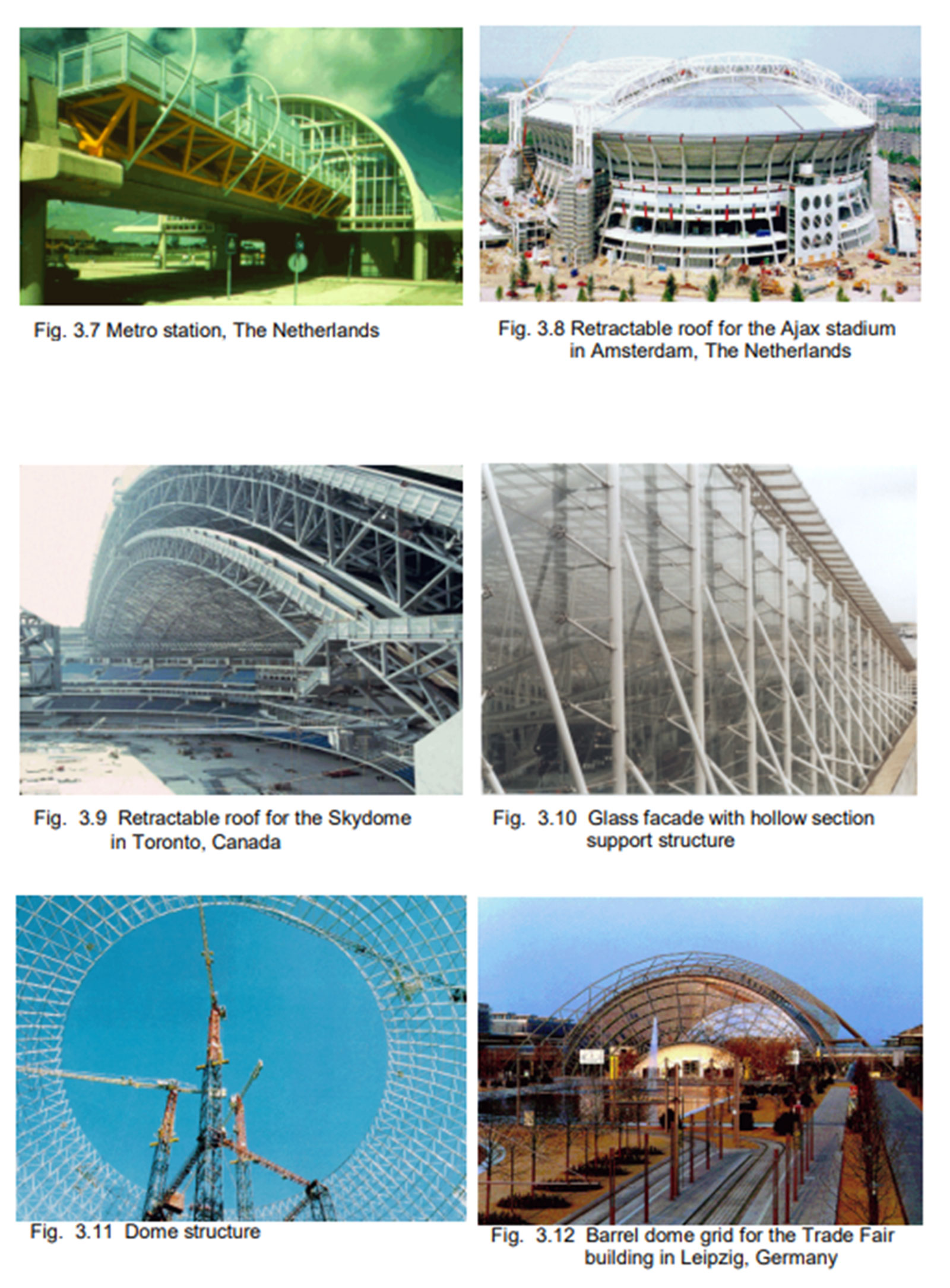

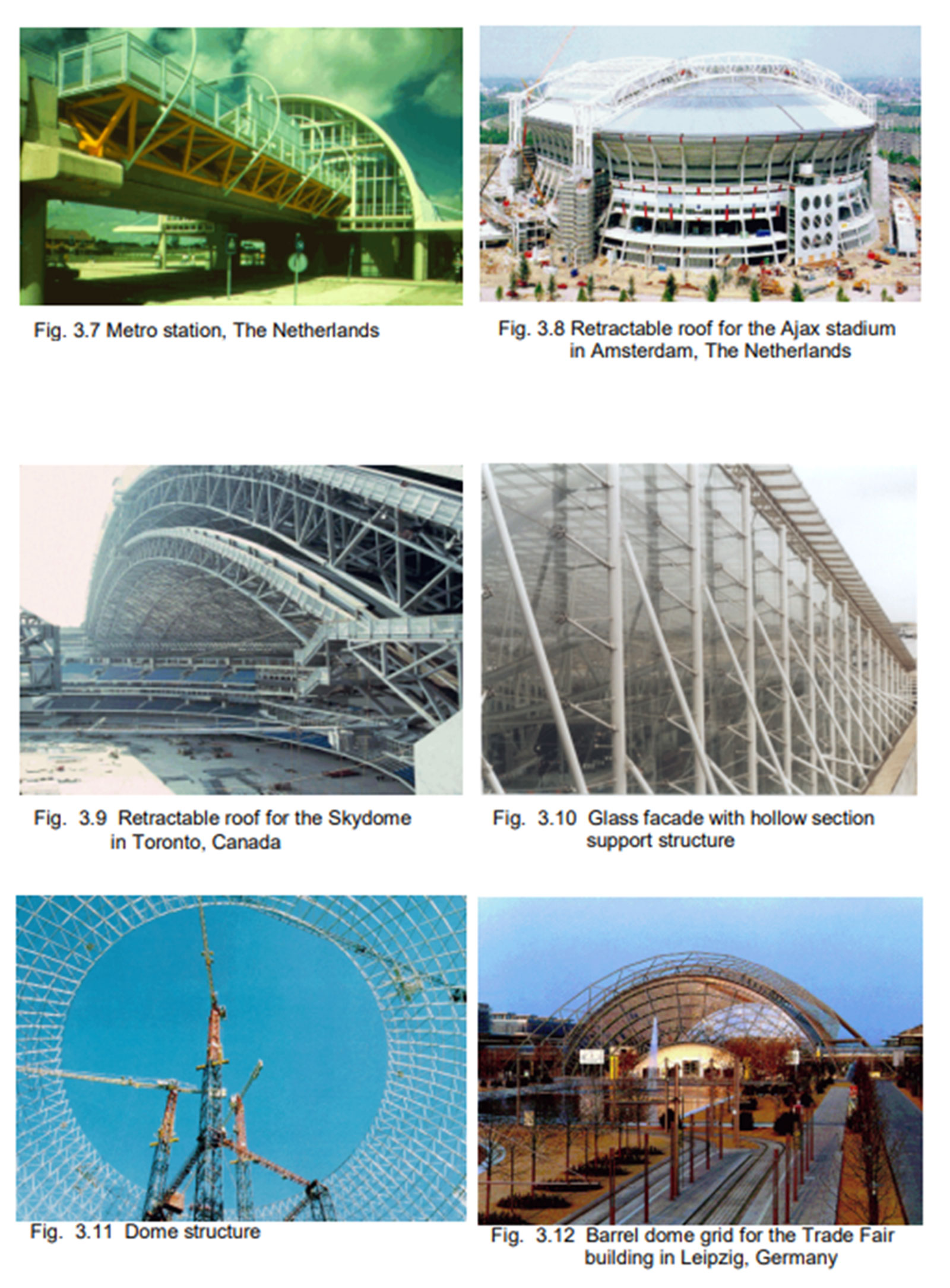

BUILDINGS, HALLS, ETC : In buildings and halls, MS Hollow Structural Sections are mainly used for columns and lattice girders or space frames for roofs. In modern architecture they are also used for other structural or architectural reasons.

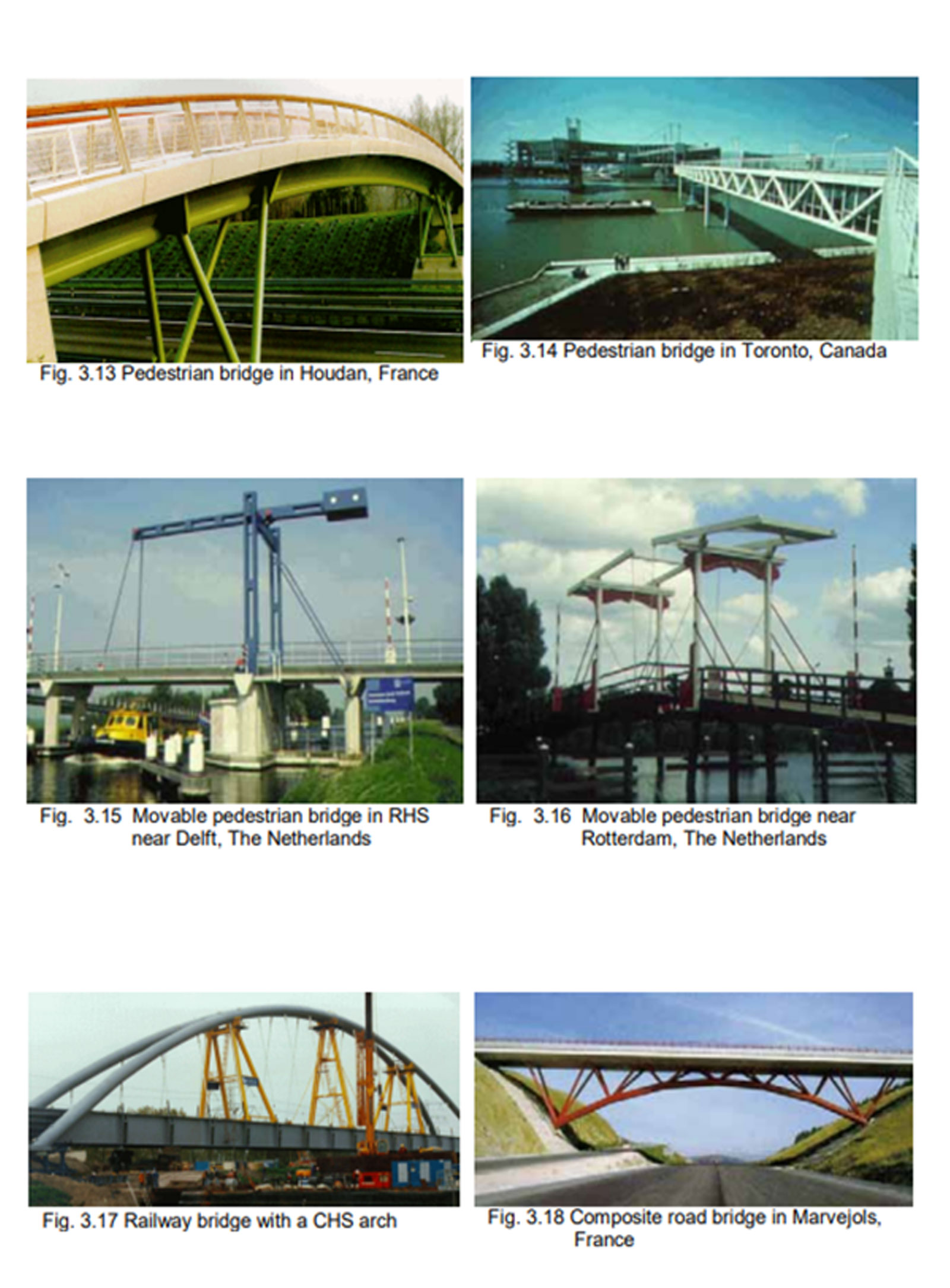

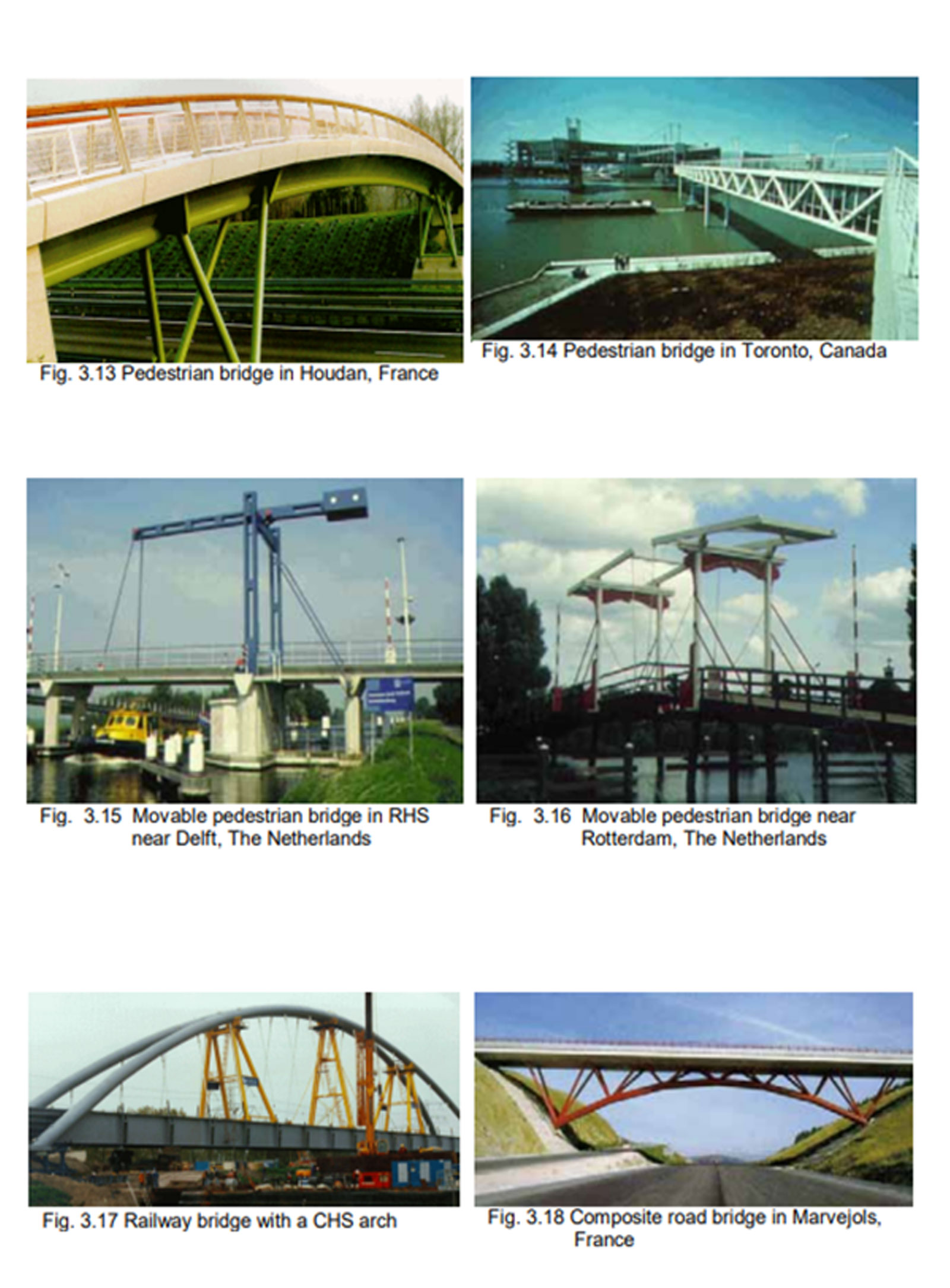

BRIDGES: As mentioned in the introduction, the Firth of Forth Bridge is an excellent example of using the hollow section shape for structural applications in bridges . Circular hollow sections are sometimes also used for the flanges of plate girders,

BARRIERS : There are a few aspects which make hollow sections increasingly used for hydraulic structures, such as barriers. Due to environmental restrictions, the maintenance of hydraulic structures requires such precautions that it is expensive ; therefore, the durability is important.

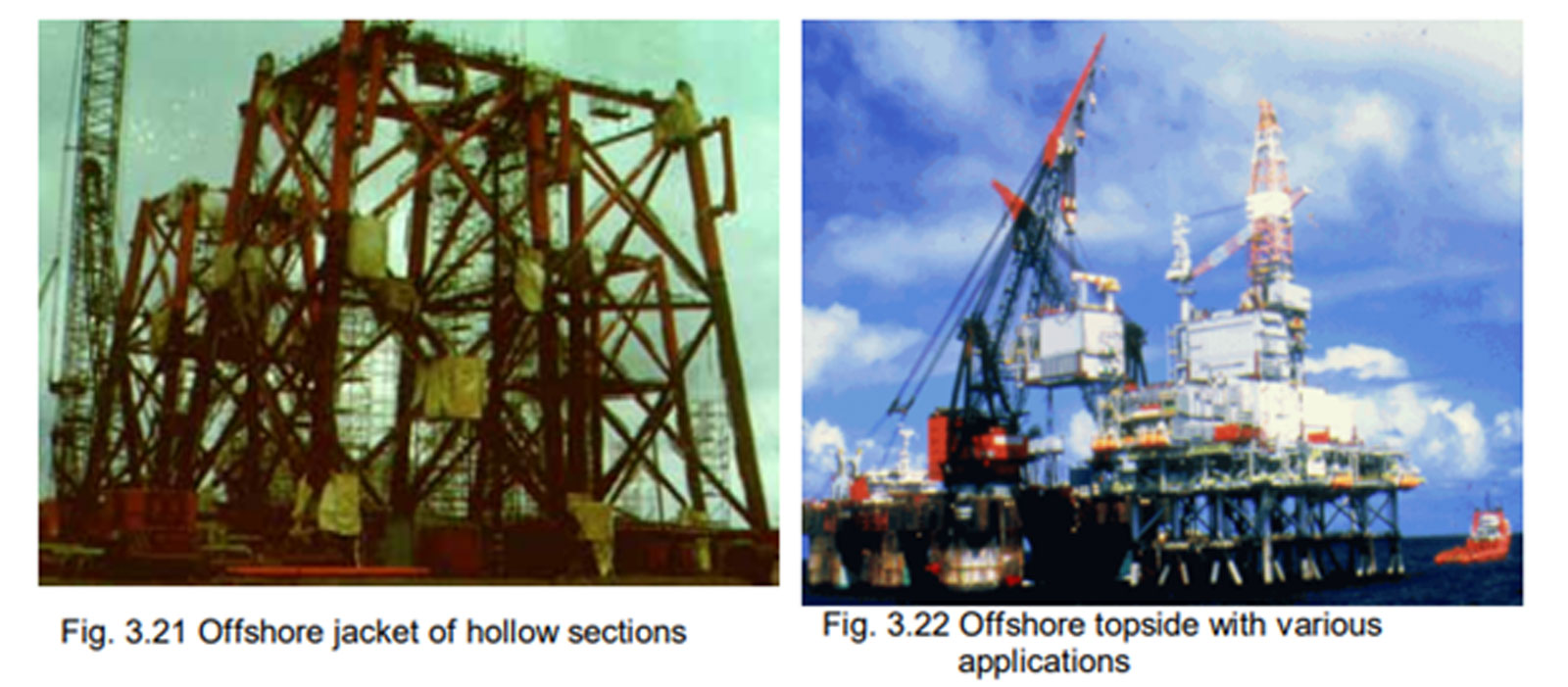

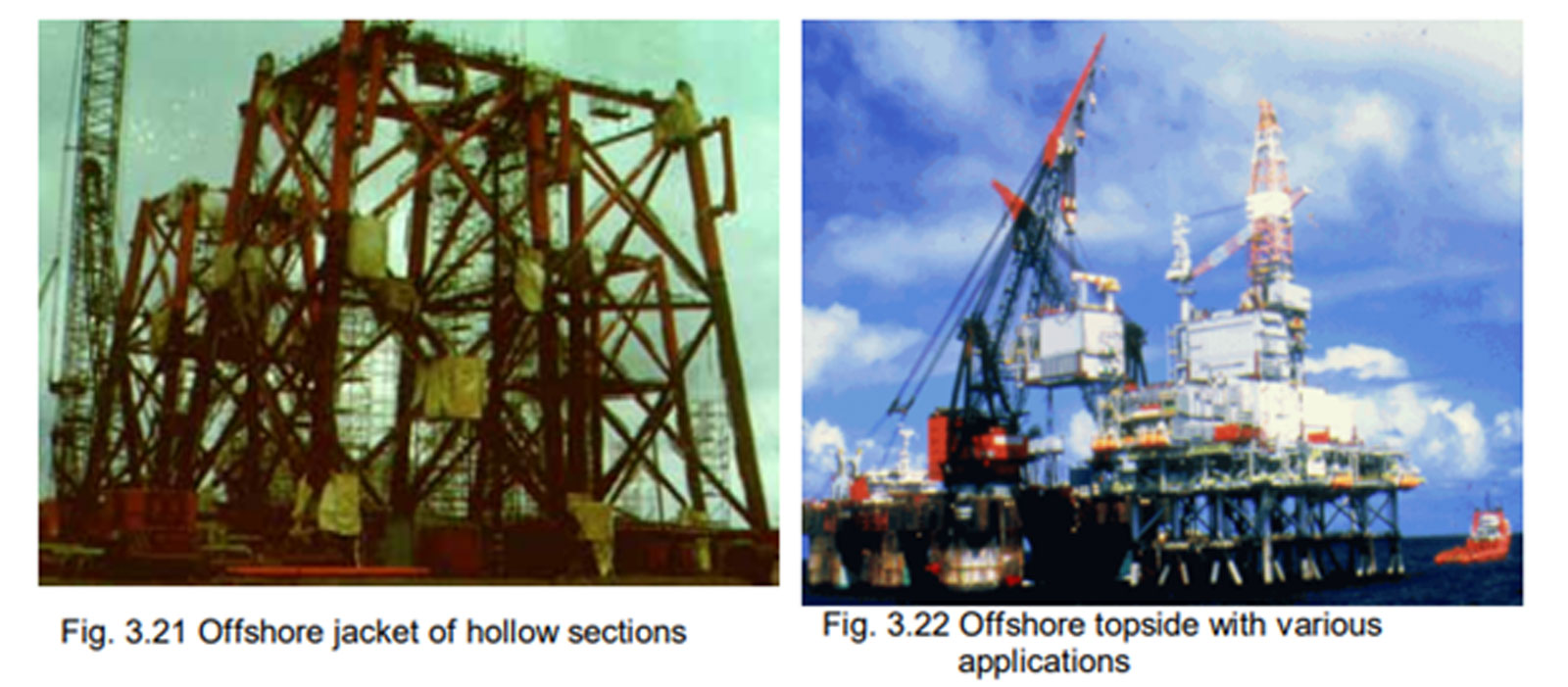

OFFSHORE STRUCTURES : Offshore, many application examples are available; most of them in circular hollow sections. For the support structure, the jacket or tower, not only is the wave loading important, but also other aspects are leading to the use of circular hollow sections.

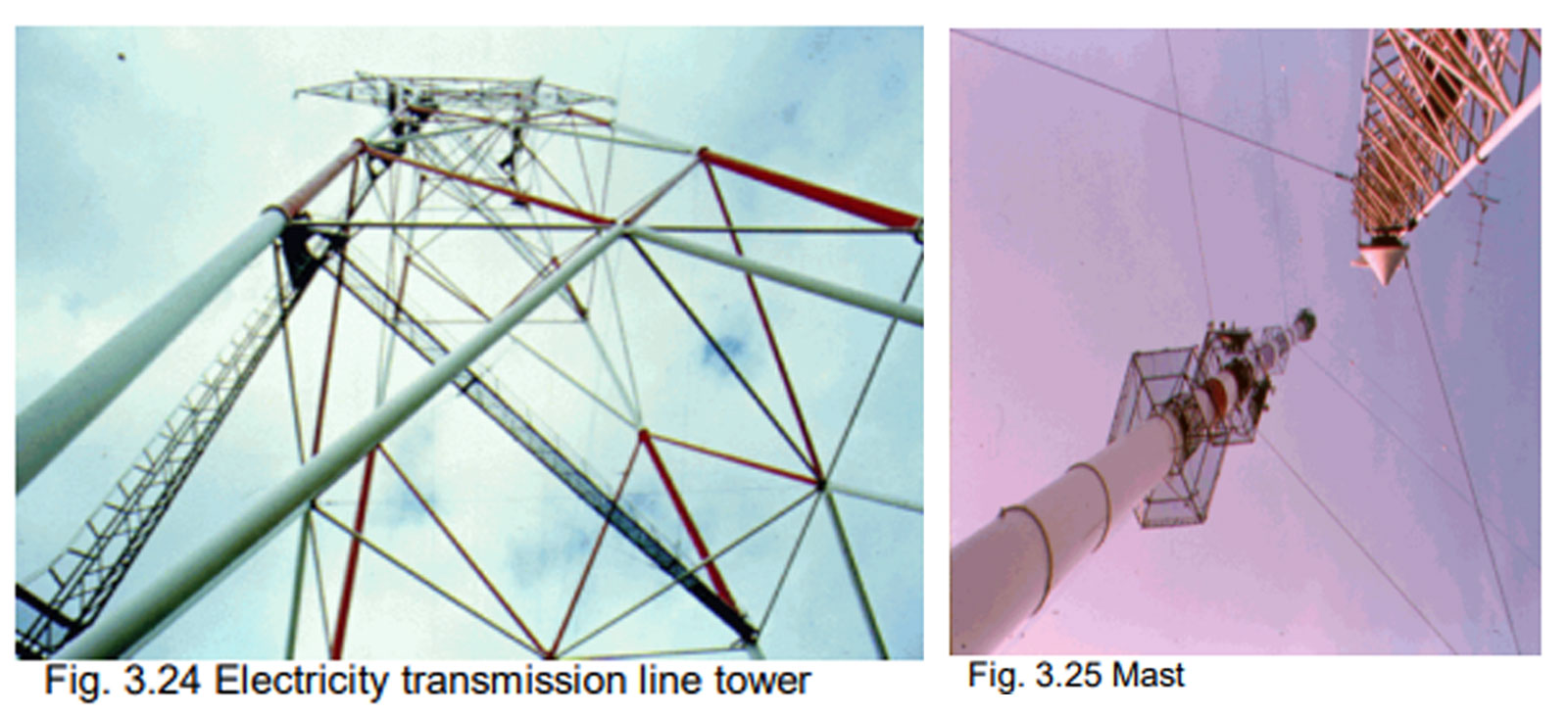

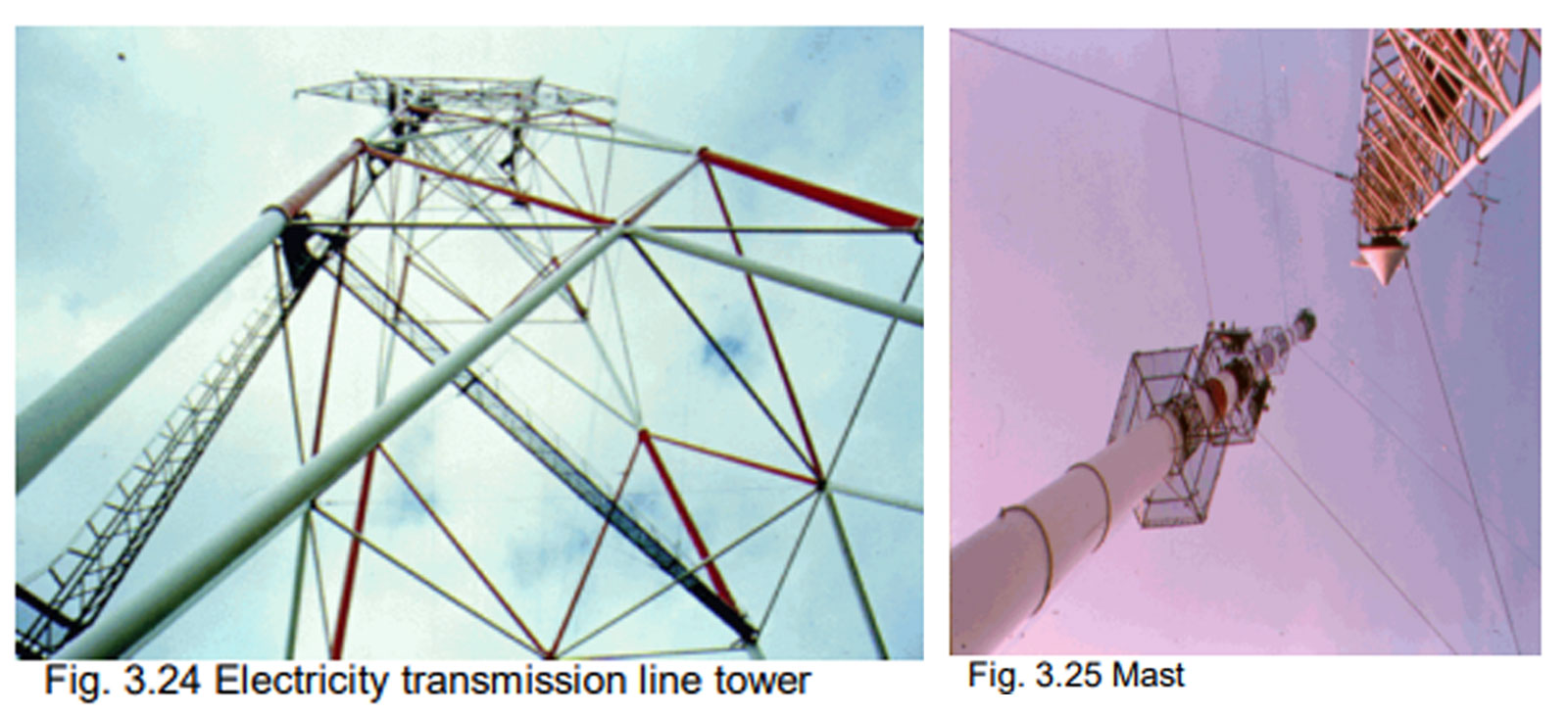

TOWERS AND MASTS : Considering wind loading, corrosion protection and architectural appearance, there is no doubt that hollow sections are to be preferred. However, in many countries, electrical transmission towers are made of angle sections with simple bolted connections. Nowadays, the protection and maintenance is more expensive.